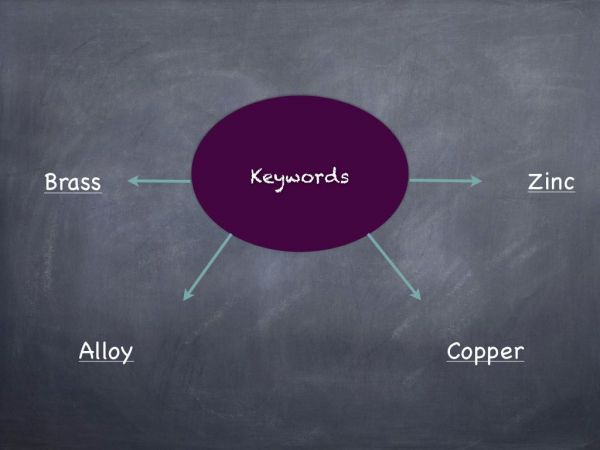

This demonstration aims to provide a chemical version of alchemy while introducing the students to the concept of alloys. This is achieved by turning a copper 5c coin, ‘gold’. As an intermediate step in the formation of a ‘gold’ coin, we will change the 5c coin ‘silver’. This will be achieved by galvanising zinc onto the copper coin. When this ‘silver’ coin is heated, an alloy, brass, is formed and the coin appears gold. This process can be linked to various industrial applications including the galvanising of iron and stainless steel to prevent rusting.

Video: Forming brass from zinc and copper

Methodology

Materials

- Beaker (250 cm3)

- Hot Plate

- Bunsen burner

- Tripod and gauze

- Pair of tongs

- Glass stirring rod

- Zinc powder/metal (5 g)

- Sodium hydroxide pellets, 24 g

- Steel wool

- 100 cm3 Distilled water

- Copper coins (5c)

Method

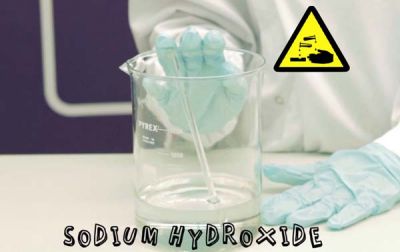

Preparation: Dissolve 24 g of sodium hydroxide pellets in 100 cm3 of deionised/distilled water in a 250 cm3 beaker, stirring continuously. The solution is concentrated (6M),will release heat and is corrosive. Heat the solution until it boils using a hot plate. When the solution boils, turn the hot plate off. Add 5 g of zinc metal/powder carefully. Sodium zincate is formed and hydrogen gas is given off. Clean the 5c coin with steel wool until it is shiny.

Demonstration:

Drop the cleaned 5c coin into the hot solution containing sodium zincate and the zinc powder/metal. Using a glass rod, ensure the coin is touching the zinc powder or metal. Leave the coin in the sodium zincate solution until it is plated with a shiny coat of zinc (2-3 mins). Remove the plated coin with tongs and rinse it under running tap water to remove residue. Show the ‘silver’ coin to the class. Using tongs, hold the plated coin in the Bunsen flame for a few seconds until the surface turns ‘gold’ (ensuring both sides are exposed to the flame). Allow the coin to cool and show it to the class.

Tips

It is important that the coin is thoroughly cleaned using the steel wool before the demonstration. Leaving the coin in the sodium zincate solution too long may cause lumps of zinc to stick to it. It is essential that the coin is rinsed before burning to remove any residue which would affect the colour change involved. Overheating the “gold” coin will cause the coin to tarnish.

*Precautions/Safety

Theory behind the hook

When the zinc is added to the boiling sodium hydroxide, a solution of sodium zincate is formed and hydrogen gas is evolved. We can see this evolution in the form of bubbles rising in the solution.

The sodium zincate solution is formed as follows:

Zn(s)+ 2NaOH(aq)+ 2H2O(l) → Na2[Zn(OH)4](aq) + H2(g)

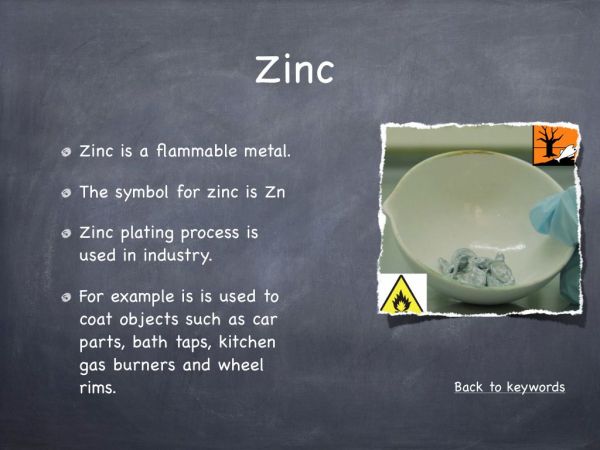

The zinc is deposited onto the 5c coin. The reaction will not occur if the copper and zinc are not touching each other. No new substance is formed. The plating of the zinc on the copper coin gives the illusion that the coin has turned ‘silver’. When this ‘silver’ coin is heated in a Bunsen, the copper and zinc combine to form an alloy called brass. This provides us with a ‘gold’ coin. Brass is an alloy of copper with between 18% and 40% of zinc and is used in musical instruments, doorknobs, locks, zippers and ammunition.

How this hook works

This hook will work best when introducing the topic of alloys, a part of the topic of metals. The video can be used to promote investigative thinking and questioning can be used to encourage the students to draw conclusions about what is happening in the video. This demonstration also illustrates the effect that heat can have on the states of substances and the process can be linked to industrially relevant processes used worldwide. A teacher could do this demonstration in class under controlled conditions and coins could be prepared earlier to give to the class. However, the demonstration involves the use of strong base and should not be carried out by students.

Questions & Answers

- What is an alloy?

An alloy is a mixture or solution of different metals. - What is the difference between an alloy and a compound?

An alloy can be made with varying composition or different ratios of components. A compound has a specific composition. They are always made with the same number of atoms from the elements involved. - Did we change a copper coin into silver?

No. The coin looks silver in colour because we have deposited a thin coating of zinc on the coin. Zinc particles adhere to the copper in the coin in a process which is similar to industrial electroplating. No new substance is formed. - Why do you think that heat is required for the coin to turn ‘gold’?

By heating the copper and zinc on the coin, they reach a liquid state which allows the molecules of the two elements to move around and mix together to the point where they form an alloy that is homogeneous or evenly mixed throughout. - How could the coin be tested to prove that it was a fake gold coin?

Even though gold is one of the heaviest metals, it is very soft. When you bite down on a piece of gold, you should leave a mark if it is pure gold, just like in the movies! Also, if the coin had a coating of another metal or alloy, biting down would scrape it and reveal the metal underneath. Today, there are more scientific methods to determine if gold is counterfeit or not.

Cross Curricular Links

A similar zinc plating process is used industrially. Links can be created to industrial processes involved in coating objects such as car parts, bath taps, kitchen gas burners, wheel rims and many others. Additionally, alloys are also used extensively in industry and have a large number of marine, medical, military, commercial, residential and manufacturing applications. Galvanizing is a method of preventing rusting and corrosion of iron or steel by coating them with zinc.